ʻO nā mea maka o nā mea i hoʻohui ʻia me ka resin, fiber a me nā mea kumu, etc.Nui nā koho, a loaʻa i kēlā me kēia mea kona ikaika kūʻokoʻa, ʻoʻoleʻa, paʻakikī a me ka paʻa wela, a ʻokoʻa hoʻi kona kumukūʻai a me kāna huahana.

Eia nō naʻe, ʻo ka mea i hoʻohui ʻia ma ke ʻano holoʻokoʻa, ʻo kāna hana hope ʻaʻole pili wale i ka resin matrix a me nā fibers (a me ke kumu kumu i ka hana sandwich), akā pili pū kekahi i ke ʻano hoʻolālā a me ke kaʻina hana o nā mea i loko o ka hale. .

E hōʻike ana kēia ʻatikala i nā ʻano hana hana composite i hoʻohana mau ʻia, nā kumu kumu nui o kēlā me kēia ʻano a pehea e koho ai i nā mea maka no nā kaʻina hana like ʻole.

ʻO ka wehewehe ʻana:He kaʻina hana e hoʻoheheʻe ʻia ai ka fiber i hoʻoikaika ʻia a me ka ʻōnaehana resin i loko o ka mold i ka manawa like, a laila ho'ōla ʻia ma lalo o ke kaomi maʻamau e hana i kahi huahana thermosetting composite.

koho mea:

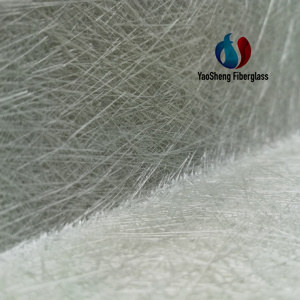

Resin: nui ka polyester

Fiber: wili aniani aniani

Mea kumu: ʻAʻohe, pono e hui pū ʻia me nā laminates kaʻawale

ʻO ka pōmaikaʻi nui:

1) He moʻolelo lōʻihi ko ka hana lima

2) ʻO ke kumukūʻai haʻahaʻa, ka fiber wikiwiki a me ka waiho ʻana o resin

3) Ke kumu kūʻai liʻiliʻi

ʻO nā hemahema nui:

1) He mea maʻalahi ka papa laminated e hana i kahi resin enriched area, a he kiʻekiʻe ke kaumaha

2) Hiki ke hoʻohana ʻia i nā ʻāpana ʻokiʻoki wale nō, kahi e kaupalena nui ai i nā waiwai mechanical o nā laminates

3) I mea e hoʻomaʻamaʻa ai i ka pīpī ʻana, pono ka haʻahaʻa o ka resin viscosity e nalowale i nā waiwai mechanical a me nā mea wela o ka mea hoʻohui.

4) ʻO ke kiʻekiʻe o ka styrene content i loko o ka spray resin, ʻo ia hoʻi nā pōʻino kiʻekiʻe aʻe i nā mea hana, a ʻo ka haʻahaʻa haʻahaʻa ʻo ia ka mea e maʻalahi ka resin e komo i nā lole hana o nā limahana a pili pono i ka ʻili.

5) He mea paʻakikī ka paʻakikī o ka styrene volatilized i ka lewa e hoʻokō i nā koi kānāwai

palapala noi maʻamau:

ʻO ka pā maʻalahi, nā papa hana haʻahaʻa haʻahaʻa e like me nā kino kaʻa hiki ke hoʻololi ʻia, nā pahu kaʻa, nā ʻauʻau a me nā waʻa liʻiliʻi.

ʻO ka wehewehe ʻana o ke ʻano:E hoʻokomo lima i nā fiber me ka resin.Hiki ke hoʻoikaika ʻia nā fiber e ka ulana ʻana, wili, humuhumu a i ʻole ka hoʻopaʻa ʻana.Hoʻohana pinepine ʻia ka hoʻopaʻa lima me nā wili a i ʻole nā pulupulu, a laila kaomi ʻia ka resin me kahi wili lāʻau e komo i nā fibers.Ua ho'ōlaʻia nā laminates ma lalo o ke kaomi maʻamau.

koho mea:

Resin: ʻaʻohe koi, epoxy, polyester, polyvinyl ester, ʻae ʻia ka resin phenolic

Fiber: ʻAʻohe koi, akā paʻakikī ke komo ʻana o ka fiber aramid me ke kaumaha kumu nui e hoʻokomo ʻia e ka lima kau ʻana

Mea kumu: ʻaʻohe koi

ʻO ka pōmaikaʻi nui:

1) He moʻolelo lōʻihi ko ka hana lima

2) Maʻalahi e aʻo

3) Inā hoʻohana ʻia ka resin curing wela, he haʻahaʻa ke kumukūʻai mold

4) Ke koho nui o nā mea a me nā mea hoʻolako

5) ʻOi aku ka nui o ka fiber, ʻoi aku ka lōʻihi o ka hoʻohana ʻana ma mua o ke kaʻina spraying

ʻO nā hemahema nui:

1) ʻO ka hui ʻana o ka resin, ka ʻike resin a me ka maikaʻi o nā laminates e pili kokoke ana i ka mākaukau o nā mea hana, paʻakikī ke loaʻa nā laminates me ka haʻahaʻa resin haʻahaʻa a me ka porosity haʻahaʻa.

2) ʻO ke olakino a me ka palekana o ka resin.ʻO ka haʻahaʻa o ke kaumaha molekala o ka resin kau lima, ʻoi aku ka nui o ka hoʻoweliweli olakino.ʻO ka haʻahaʻa o ka viscosity, ʻoi aku ka maʻalahi o ka resin e komo i loko o nā lole hana o nā limahana a pili pono i ka ʻili.

3) Inā ʻaʻole i hoʻokomo ʻia nā mea hoʻonaninani maikaʻi, paʻakikī ke hoʻokō ʻana i nā koi kānāwai.

4) Pono e haʻahaʻa loa ka viscosity o ka resin lay-up, no laila e kiʻekiʻe ka ʻike o ka styrene a i ʻole nā mea hoʻoheheʻe ʻē aʻe, no laila e nalowale ana nā waiwai mechanical/thermal o ka mea hoʻohui.

Nā noi maʻamau:ʻO nā ʻūhā huila makani maʻamau, nā waʻa i hana nui ʻia, nā kumu hoʻohālike

ʻO ka wehewehe ʻana:ʻO ke kaʻina hana ʻeke ʻeke he hoʻonui ʻia o ke kaʻina hana kau lima i ʻōlelo ʻia ma luna nei, ʻo ia hoʻi, ua hoʻopaʻa ʻia kahi papa o ka kiʻiʻoniʻoni i hoʻopaʻa ʻia ma ka mold e hoʻomaʻemaʻe i ka laminate i kau ʻia e ka lima, a ua hoʻopili ʻia kahi kaomi lewa i ka laminate e hoʻokō ai. ka hopena o ka pau a me ka hoʻopili.No ka hoʻomaikaʻi ʻana i ka maikaʻi o nā mea hoʻohuihui.

koho mea:

Resin: ʻaʻole kūpono ka epoxy a me ka resin phenolic, polyester a me ka polyvinyl ester no ka mea aia lākou i ka styrene, e hoʻoheheʻe ʻia i loko o ka pā

Fiber: ʻAʻohe koi, ʻo nā fiber me ke kaumaha kumu nui hiki ke pulu ma lalo o ke kaomi

Mea kumu: ʻaʻohe koi

ʻO ka pōmaikaʻi nui:

1) Hiki ke hoʻokō i ka maʻiʻo fiber kiʻekiʻe ma mua o ke kaʻina hana kau lima maʻamau

2) He haʻahaʻa ka porosity ma mua o ke kaʻina hana kau lima maʻamau

3) Ma lalo o ke kūlana o ke kaomi maikaʻi ʻole, hoʻomaikaʻi ke kahe piha o ka resin i ke kiʻekiʻe o ka pulu ʻana o nā fiber.ʻOiaʻiʻo, e hoʻopili ʻia kahi ʻāpana o ka resin e nā mea hoʻohana ʻole

4) ʻO ke olakino a me ka palekana: Hiki i ke kaʻina hana ʻeke ʻeke ke hōʻemi i ka hoʻokuʻu ʻana o nā volatiles i ka wā mālama

ʻO nā hemahema nui:

1) Hoʻonui nā kaʻina hana hou i ke kumukūʻai o ka hana a me nā mea ʻeke ʻeke ʻeke hoʻolele

2) Nā koi ʻenehana kiʻekiʻe no nā mea hana

3) ʻO ka mana o ka hui ʻana o ka resin a me ka ʻike resin e hilinaʻi nui ʻia i ka mākaukau o ka mea hana

4) ʻOiai ke hoʻemi nei ka ʻeke pahu i ka hoʻokuʻu ʻana o nā volatiles, ʻoi aku ka kiʻekiʻe o ka hoʻoweliweli olakino i ka mea hoʻohana ma mua o ka infusion a i ʻole kaʻina prepreg.

Nā noi maʻamau:nui, hoʻokahi manawa hoʻopuka palena ʻia, nā ʻāpana kaʻa heihei, ka hoʻopaʻa ʻana o nā mea nui i ka hana moku.

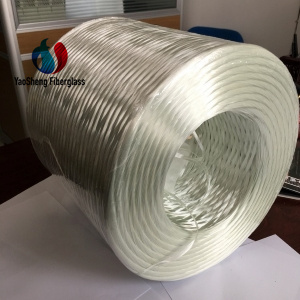

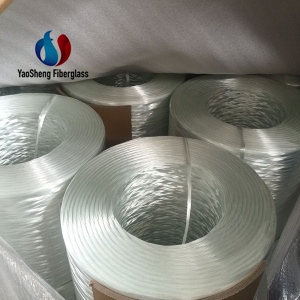

ʻO Deyang Yaosheng Composite Material Co., Ltd.he hui ʻoihana e hana ana i nā huahana fiber aniani like ʻole.Hana nui ka hui i ka Fiberglass roving, aniani fiber i ʻoki ʻia i ka moena strand, aniani fiber cloth/roving fabric/marine, etc. E ʻoluʻolu e kelepona mai iā mākou.

Kelepona: +86 15283895376

Whatsapp: +86 15283895376

Email: yaoshengfiberglass@gmail.com

ʻO ka wehewehe ʻana o ke ʻano:Hoʻohana ʻia ke kaʻina hana wili no ka hana ʻana i nā ʻāpana hollow, puni a oval paha e like me nā paipu a me nā pahu.Ma hope o ka hoʻokomoʻiaʻana o ka pūpū fiber me ka resin, uaʻeha ia ma ka mandrel ma nāʻaoʻao likeʻole, a ke hoʻomaluʻia ke kaʻina hana e ka mīkini wiliwili a me ka wikiwiki o ka mandrel.

koho mea:

Resin: ʻaʻohe koi, e like me ka epoxy, polyester, polyvinyl ester a me ka resin phenolic, etc.

Fiber: ʻaʻohe koi, hoʻohana pololei i ka pūpū fiber o ka creel, ʻaʻohe pono e ulana a humuhumu i ka lole fiber

Mea koʻikoʻi: ʻaʻohe koi, akā ʻo ka ʻili ka mea maʻamau i hoʻokahi-layer composite material

ʻO ka pōmaikaʻi nui:

1) He wikiwiki ka wikiwiki o ka hana ʻana, a he ʻano hoʻokele waiwai a kūpono hoʻi

2) Hiki ke hoʻomalu ʻia ka ʻike resin ma ke ana ʻana i ka nui o ka resin i lawe ʻia e ka pūpū fiber e hele ana ma ka pahu resin.

3) E hoʻemi i ke kumukūʻai fiber, ʻaʻohe kaʻina hana ulana waena

4) He maikaʻi ka hana hoʻolālā, no ka mea, hiki ke waiho ʻia nā pūʻulu fiber linear i nā ʻano like ʻole.

ʻO nā hemahema nui:

1) Ua kaupalena ʻia kēia kaʻina hana i nā hale hollow pōʻai

2) ʻAʻole maʻalahi ka hoʻonohonoho pono ʻana o nā fibers ma ke kuhikuhi axial o ka mea

3) He kiʻekiʻe ke kumukūʻai o ka mandrel male mold no nā ʻāpana kūkulu nui

4) ʻO ka ʻaoʻao o waho o ka hale ʻaʻole ia ka ʻili o ka mold, no laila ʻilihune nā mea nani

5) I ka hoʻohana ʻana i ka resin viscosity haʻahaʻa, pono e uku ʻia i ka hana kemika a me ka hana olakino a palekana.

Nā noi maʻamau:nā pahu hoʻopaʻa kemika a me nā paipu hoʻouna, nā pahu pahu, nā pahu hanu ahi

ʻO ka wehewehe ʻana:Hoʻopili ʻia ka pūpū fiber i huki ʻia mai ka creel a hele i loko o ka pā wela, a hoʻokomo ʻia ka resin i loko o ka fiber ma ka pā wela, a mālama ʻia ka ʻike resin, a ma hope e hoʻōla ʻia ka mea i ke ʻano i makemake ʻia;ʻoki ʻia kēia huahana hoʻoponopono i hoʻopaʻa ʻia i ka mīkini i nā lōʻihi like ʻole.Hiki i nā fiber ke komo i ka pā wela ma nā ʻaoʻao ʻē aʻe ma mua o 0 degere.

ʻO ka Pultrusion kahi kaʻina hana hoʻomau, a ʻo ka ʻāpana keʻa o ka huahana maʻamau ke ʻano paʻa, e ʻae ana i nā loli liʻiliʻi.E hoʻopaʻa i ka mea pulu mua e hele ana ma ka pā wela a hohola i loko o ka poʻi no ka ho'ōla koke ʻana.ʻOiai he maikaʻi ʻole ka hoʻomau ʻana o kēia kaʻina hana, hiki iā ia ke hoʻololi i ke ʻano keʻa.

koho mea:

Resin: maʻamau epoxy, polyester, polyvinyl ester a me phenolic resin, etc.

Fiber: ʻaʻohe koi

Mea kumu: ʻaʻole hoʻohana maʻamau

ʻO ka pōmaikaʻi nui:

1) He wikiwiki ka wikiwiki o ka hana, a he ala kūpono a kūpono hoʻi e hoʻomaʻemaʻe a hoʻōla i nā mea

2) Ka mana pololei o ka ʻike resin

3) E hoʻemi i ke kumukūʻai fiber, ʻaʻohe kaʻina hana ulana waena

4) Hana maikaʻi loa, no ka mea, ua hoʻonohonoho ʻia nā pūʻulu fiber i kahi laina pololei a kiʻekiʻe ka hapa nui o ka fiber.

5) Hiki ke hoʻopaʻa paʻa ʻia ka wahi infiltration fiber e hoʻemi i ka hoʻokuʻu ʻana o nā volatiles

ʻO nā hemahema nui:

1) Hoʻopili kēia kaʻina hana i ke ʻano keʻa

2) He kiʻekiʻe ke kumukūʻai o ka pā wela

Nā noi maʻamau:ʻO nā kaola a me nā pahu no nā hale, nā alahaka, nā alapiʻi a me nā pā

6. Hoʻololi Resin Molding (RTM)

ʻO ka wehewehe ʻana:E kau i nā pulu maloʻo i loko o ka ʻeleʻele haʻahaʻa, e hoʻopili i ke kaomi ma mua e hana i nā fibers e kūpono i ke ʻano o ka ʻōpala e like me ka hiki, a hoʻopaʻa iā lākou;a laila, e hoʻopaʻa i ka poʻi luna ma luna o ka poʻi lalo e hana i kahi lua, a laila e hoʻokomo i ka resin i loko o ka lua mold.

Hoʻohana pinepine ʻia ka hoʻoheheʻe ʻana i ka resin a me ka infiltration o nā fibers, ʻo ia hoʻi ke kaʻina hana infusion resin i kōkua ʻia (VARI).Ke hoʻopau ʻia ka infiltration fiber, pani ʻia ka valve hoʻokomo resin a hoʻōla ʻia ka composite.Hiki ke hana ʻia ka hoʻoheheʻe ʻana a me ka hoʻōla ʻana ma ka lumi wela a i ʻole ma lalo o nā kūlana wela.

koho mea:

Resin: maʻamau epoxy, polyester, polyvinyl ester a me ka resin phenolic, hiki ke hoʻohana ʻia ka resin bismaleimide i ka wela kiʻekiʻe

Fiber: ʻAʻohe koi.ʻOi aku ka maikaʻi o nā fiber humuhumu no kēia kaʻina hana no ka mea e maʻalahi ka hoʻoili ʻana o ka resin;aia nā fiber i hoʻomohala kūikawā e hoʻomaʻamaʻa i ka kahe resin

Mea kumu: ʻAʻole kūpono ka honeycomb foam, no ka mea, e hoʻopiha ʻia nā cellcomb cell i ka resin, a ʻo ke kaomi ka mea e hāʻule ai ka huʻa.

ʻO ka pōmaikaʻi nui:

1) Ka hapa nui o ka fiber a me ka porosity haʻahaʻa

2) No ka hoʻopaʻa paʻa ʻia o ka resin, olakino a palekana, a maʻemaʻe a maʻemaʻe ke kaiapuni hana

3) E ho'ēmi i ka hoʻohana hana

4) ʻO nā ʻaoʻao o luna a me lalo o ka ʻaoʻao hoʻolālā he mau papa lepo, kahi maʻalahi no ka mālama ʻana ma hope.

ʻO nā hemahema nui:

1) He pipiʻi ka mold i hoʻohana pū ʻia, a i mea e pale aku ai i ke koʻikoʻi nui, ua kaumaha a paʻakikī.

2) Ua kaupalena ʻia i ka hana ʻana i nā ʻāpana liʻiliʻi

3) Hiki ke ʻike ʻia nā wahi ʻaʻole i pulu ʻia, e hopena i ka nui o ka ʻōpala

Nā noi maʻamau:kaʻa kaʻa liʻiliʻi a paʻakikī, nā noho kaʻaahi

7. Nā kaʻina hana perfusion - SCRIMP, RIFT, VARTM, etc.

Ka wehewehe ʻana:E waiho i nā pulu maloʻo e like me ke kaʻina hana RTM, a laila e waiho i ka lole hoʻokuʻu a me ka ʻupena wai.Ma hope o ka pau ʻana o ka waiho ʻana, ua hoʻopaʻa ʻia me kahi ʻeke ʻeke, a i ka wā e hiki ai ka ʻōpala i kahi koi, ua hoʻokomo ʻia ka resin i loko o ka hale layup holoʻokoʻa.Loaʻa ka hāʻawi ʻana i ka resin i ka laminate ma ke alakaʻi ʻana i ke kahe resin ma o ka ʻupena alakaʻi, a ma hope o ka hoʻopili piha ʻana o nā pulu maloʻo mai luna a lalo.

koho mea:

Resin: epoxy, polyester, polyvinyl ester resin

Fiber: ʻO kēlā me kēia fiber maʻamau.ʻOi aku ka maikaʻi o nā fiber i humuhumu ʻia no kēia kaʻina hana e like me ka wikiwiki o ka hoʻoili resin

Mea koʻikoʻi: ʻaʻole pili ʻia ka ʻūhā honeycomb

ʻO ka pōmaikaʻi nui:

1) E like me ke kaʻina hana RTM, akā hoʻokahi ʻaoʻao i hoʻoheheʻe ʻia

2) ʻO kekahi ʻaoʻao o ka mold he ʻeke ʻeke, kahi e mālama nui ai i ke kumukūʻai o ka mold a hoʻemi i ka koi no ka ʻōpala e kū i ke kaomi.

3) Hiki i nā ʻāpana hoʻolālā nui ke loaʻa ka hapa nui o ka fiber a me ka porosity haʻahaʻa

4) Hiki ke hoʻohana ʻia ke kaʻina hana kau lima maʻamau no kēia kaʻina hana ma hope o ka hoʻololi ʻana

5) Hiki ke hoʻoheheʻe ʻia ke ʻano hana sandwich i hoʻokahi manawa

ʻO nā hemahema nui:

1) No nā hale nui, paʻakikī ke kaʻina hana, ʻaʻole hiki ke pale ʻia ka hoʻoponopono

2) Pono e haʻahaʻa loa ka viscosity o ka resin, e hoʻemi ana i nā waiwai mechanical

3) Hiki ke ʻike ʻia nā wahi ʻaʻole i pulu ʻia, e hopena i ka nui o ka ʻōpala

Nā noi maʻamau:Hana ʻia ka hoʻāʻo ʻana o nā waʻa liʻiliʻi, nā panela kino no nā kaʻaahi a me nā kaʻa, nā ʻili makani turbine

8. Prepreg - kaʻina hana autoclave

ʻO ka wehewehe ʻana:ʻO ka fiber a i ʻole ka lole fiber i hoʻopili mua ʻia e ka mea hana mea me kahi resin i loaʻa i ka catalyst, a ʻo ke ʻano hana he kiʻekiʻe kiʻekiʻe a me ke ʻano kaomi kiʻekiʻe a i ʻole ke ʻano hoʻoheheʻe solvent.Hoʻopaneʻe ka catalyst ma ka lumi wela, e hāʻawi ana i ka waiwai i ke ola o nā hebedoma a i ʻole mau mahina ma ke ana wela;hiki i ka pahu hau ke hooloihi i kona ola.

Hiki i ka prepreg ke waiho i ka lima a i ʻole ka mīkini ma luna o ka ʻili o ka ʻōpala, a laila uhi ʻia i loko o kahi ʻeke a hoʻomehana ʻia i 120-180 ° C.Ma hope o ka hoʻomehana ʻana, hiki ke kahe hou ka resin a hoʻōla hope.Hiki ke hoʻohana ʻia kahi autoclave e hoʻopili i ke kaomi hou i ka mea, maʻamau a hiki i 5 mau ea.

koho mea:

Resin: hiki ke hoʻohana ʻia ka epoxy, polyester, phenolic resin, kiʻekiʻe wela wela e like me polyimide, cyanate ester a me bismaleimide.

Fiber: ʻAʻohe koi.Hiki ke hoʻohana ʻia ka pūʻolo fiber a i ʻole ka lole fiber

Mea kumu: ʻaʻohe koi, akā pono ke kūʻē i ka wela kiʻekiʻe a me ke kaomi kiʻekiʻe

ʻO ka pōmaikaʻi nui:

1) Hoʻonohonoho pololei ʻia ka ratio o ka resin i ka curing agent a me ka ʻike resin e ka mea hoʻolako, maʻalahi loa ka loaʻa ʻana o nā laminates me ka nui o ka fiber a me ka porosity haʻahaʻa.

2) He mau hiʻohiʻona olakino maikaʻi a palekana ka mea, a maʻemaʻe ke kaiapuni hana, hiki ke mālama i ka automation a me nā koina hana.

3) Hoʻemi ʻia ke kumukūʻai o nā fibers unidirectional material, ʻaʻole pono ke kaʻina hana waena e ulana i nā fibers i ka lole.

4) Pono ke kaʻina hana i ka resin me ka viscosity kiʻekiʻe a me ka wettability maikaʻi, a me nā waiwai mechanical a me ka wela.

5) ʻO ka hoʻonui ʻia ʻana o ka manawa hana ma ka lumi wela ka mea e maʻalahi ka hoʻokō ʻana i ka hoʻolālā a me ka waiho ʻana o nā ʻano paʻakikī.

6) Hiki ke mālama ʻia ma ka automation a me nā koina hana

ʻO nā hemahema nui:

1) Piʻi ke kumukūʻai o nā mea waiwai, akā ʻaʻole hiki ke pale ʻia i mea e hoʻokō ai i nā koi noi

2) Pono kahi autoclave e hoʻopau i ka curing, he kumu kūʻai kiʻekiʻe, lōʻihi ka manawa hana a me nā palena nui.

3) Pono ka mold e kū i ka wela kaʻina hana kiʻekiʻe, a loaʻa nā mea koʻikoʻi i nā koi like

4) No nā ʻāpana ʻoi aku ka mānoanoa, koi ʻia ka pre-vacuum i ka wā e waiho ana i nā prepregs e hoʻopau i nā ʻōpū ea interlayer

Nā noi maʻamau:nā ʻāpana hoʻokele kaʻa (e like me nā ʻēheu a me nā huelo), nā kaʻa heihei F1

9. Prepreg - kaʻina non-autoclave

ʻO ka wehewehe ʻana:ʻO ke kaʻina hana hana prepreg haʻahaʻa haʻahaʻa haʻahaʻa e like me ka autoclave prepreg, ʻo ka ʻokoʻa, ʻo nā waiwai kemika o ka resin e hiki ke ho'ōla ʻia ma 60-120 ° C.

No ka ho'ōla haʻahaʻa haʻahaʻa 60 ° C, hoʻokahi pule wale nō ka manawa hana o ka mea;no nā catalysts kiʻekiʻe (> 80 ° C), hiki i ka manawa hana ke hiki i kekahi mau mahina.ʻO ka wai o ka ʻōnaehana resin e hiki ai ke hoʻōla me ka hoʻohana ʻana i nā ʻeke vacuum wale nō, e pale aku i ka hoʻohana ʻana i nā autoclaves.

koho mea:

Resin: ʻO ka resin epoxy wale nō

Fiber: ʻaʻohe koi, e like me ka prepreg kahiko

Mea kumu: ʻaʻohe koi, akā pono e uku ʻia i ka wā e hoʻohana ai i ka pahu PVC maʻamau

ʻO ka pōmaikaʻi nui:

1) Loaʻa iā ia nā pono āpau o ka prepreg autoclave kuʻuna ((i.))-((vi.))

2) He ʻuʻuku ka mea hoʻoheheʻe, e like me ka lāʻau, no ka mea haʻahaʻa ka mahana hoʻōla

3) Hoʻomaʻamaʻa ʻia ke kaʻina hana o nā ʻāpana hoʻolālā nui, pono wale e kaomi i ka ʻeke pahu, e hoʻopuʻi i ka ea wela o ka umu a i ʻole ka ʻōnaehana hoʻomehana wela o ka mold ponoʻī e hoʻokō i nā koi hoʻōla.

4) Hiki ke hoʻohana pū ʻia nā mea ʻala maʻamau, a ʻoi aku ka oʻo o ke kaʻina hana

5) Ke hoʻohālikelike ʻia me ka autoclave, ʻoi aku ka haʻahaʻa o ka ikehu

6) ʻO ka ʻenehana kiʻekiʻe e hōʻoia i ka pololei o ka dimensional a me ka hana hou

ʻO nā hemahema nui:

1) ʻoi aku ka kiʻekiʻe o ke kumu kūʻai ma mua o ka fiber maloʻo, ʻoiai ʻoi aku ka haʻahaʻa o ka resin ma mua o ka aerospace prepreg

2) Pono ka mold e kū i kahi mahana kiʻekiʻe ma mua o ke kaʻina hana infusion (80-140 ° C)

Nā noi maʻamau:kiʻekiʻe kiʻekiʻe-performing wind turbine nā waʻa heihei nui a me nā yachts, hoʻopakele mokulele, nā mea kaʻaahi

10. Non-autoclave kaʻina o semi-preg SPRINT/beam prepreg SparPreg

ʻO ka wehewehe ʻana:He mea paʻakikī ka hoʻokuʻu ʻana i nā ʻōhū ea ma waena o nā papa a i ʻole nā papa i ka wā o ka hoʻōla ʻana i ka wā e hoʻohana ai i ka prepreg i nā hale mānoanoa (>3mm).I mea e lanakila ai i kēia paʻakikī, ua hoʻokomo ʻia ka pre-vacuumization i ke kaʻina hana layering, akā ua hoʻonui nui ʻia ka manawa kaʻina.

I nā makahiki i hala iho nei, ua hoʻolauna ʻo Gurit i kahi ʻano o nā huahana prepreg i hoʻomaikaʻi ʻia me ka ʻenehana patented, e hiki ai i ka hana ʻana i nā laminates mānoanoa kiʻekiʻe (haʻahaʻa porosity) e hoʻopau ʻia i kahi kaʻina hana hoʻokahi.Hoʻokumu ʻia ka SPRINT semi-preg i ʻelua papa o ka ʻili maloʻo sandwiching i kahi papa o ka resin film sandwich structure.Ma hope o ka waiho ʻia ʻana o nā mea i loko o ka mold, hiki i ka ʻōpala ʻūhā ke hoʻokahe piha i ka ea i loko o ia mea ma mua o ka wela o ka resin a palupalu a hoʻoheheʻe i ka fiber.hoʻopaʻa ʻia.

ʻO ka Beam prepreg SparPreg kahi prepreg i hoʻomaikaʻi ʻia, i ka wā e ho'ōla ʻia ai ma lalo o ka momi, hiki iā ia ke wehe maʻalahi i nā ʻōhū ea mai ka mea i hoʻopaʻa ʻia.

koho mea:

Resin: ka hapa nui o ka epoxy resin, loaʻa pū kekahi resins

Fiber: ʻaʻohe koi

Mea kumu: ʻo ka hapa nui, akā pono e uku ʻia ka nānā kūikawā i ka wela kiʻekiʻe i ka wā e hoʻohana ai i ka pahu PVC maʻamau

ʻO ka pōmaikaʻi nui:

1) No nā ʻāpana ʻoi aku ka mānoanoa (100mm), hiki ke loaʻa pololei i ka hakina leo fiber kiʻekiʻe a me ka porosity haʻahaʻa.

2) Paʻa ke kūlana mua o ka ʻōnaehana resin, a ʻoi aku ka maikaʻi o ka hana ma hope o ka hoʻōla ʻana i ka wela

3) E ʻae i ka hoʻohana ʻana i ka lole fiber kiʻekiʻe ke kumu kūʻai haʻahaʻa (e like me 1600 g / m2), hoʻonui i ka wikiwiki o ka waiho ʻana, a mālama i nā kumukūʻai hana.

4) He holomua loa ke kaʻina hana, maʻalahi ka hana a mālama pono ʻia ka ʻike resin

ʻO nā hemahema nui:

1) ʻoi aku ka kiʻekiʻe o ke kumu kūʻai ma mua o ka fiber maloʻo, ʻoiai ʻoi aku ka haʻahaʻa o ka resin ma mua o ka aerospace prepreg

2) Pono ka mold e kū i kahi mahana kiʻekiʻe ma mua o ke kaʻina hana infusion (80-140 ° C)

Nā noi maʻamau:kiʻekiʻe kiʻekiʻe-hana makani turbine lau, nui heihei waʻa a me nā yachts, hoʻopakele mokulele

Ka manawa hoʻouna: Dec-13-2022